An overview of the company's history

Boredom is said to be the best prerequisite for good ideas. Perhaps that is why so many ingenious inventions are born during the long, dark winters in the Black Forest. When the field work is at a standstill and snow lies heavy on the large roofs of remote farms, it is time to tinker in the parlours – for example, on technical problems.

It is this Black Forest inventive spirit, a combination of creativity and pragmatism, that also inspires Emil Frei. However, his company will not be bringing watches or machines to market. Nor do his employees tinker with precision mechanical processes, but rather with highly explosive formulas. FreiLacke is one of the few chemical companies in the Schwarzwald-Baar district, yet it is a typical Black Forest success story for a medium-sized company.

Emil Frei was born in 1885 on a farm in Döggingen. After finishing school, he worked in the sales department of a paint factory and set up a sales base in his parents' house in 1909. At the same time, he searched for suitable plots of land on which to build his own company. He finally built the first company building at Döggingen railway station, a combination of office, warehouse and residential building with an astonishingly large hall. If his planned paint wholesale business failed, Emil Frei wanted to open a station restaurant here. However, the First World War and its aftermath initially prevented Emil Frei from pursuing his dreams.

In the 1920s, he finally opened a wholesale paint business. In the sales rooms, Emil Frei advised painters and varnishers with great passion and expertise. He soon came up with the idea of not only selling finished products and standard paints, but also manufacturing paints, varnishes and fillers himself in order to offer tailor-made, individual and even better solutions.

Word of this service spreads. Soon, Emil Frei and his paint factory are known far beyond the borders of Döggingen.

It is a cold winter's day in Döggingen, with snow covering the yard. Although it is Sunday, the paint factory is busy. Panting, several men drag and haul sacks and buckets to the tracks. A wagon has been waiting there since the previous day to be loaded. Later, when the freight train from Neustadt passes Döggingen again, it will couple up the wagon and transport the goods to their destination.

One of the men working in Döggingen on this cold Sunday during the war winter is Josef Buri. He has been employed in production since 1941. "The freight had to be loaded by half past three. In winter with a sledge and in summer with a small cart."

One of the major customers ensuring the company's continued existence during these years is the Deutsche Reichsbahn. The location at the railway station in Döggingen proves to be an important advantage for the Frei company, especially during the war years. Petrol and diesel are strictly rationed, and even during air raids, the railway network remains operational well into 1944.

In April 1945, German units coming from the Breg Valley march through Bräunlingen towards Döggingen. The soldiers attempt to fight their way to the border to avoid capture.[1] On 8 May, the war ends with Germany's unconditional surrender.

The memories of this period are dark. Shortly before the end of the war, Emil Frei's wife is killed by machine gun fire from a French tank. One of his three sons, Franz, returns late from Russian captivity. The experiences of these years shape him for the rest of his life.

After the war, Emil Frei devoted himself wholeheartedly to his work. The paint factory became his life's work. And the fateful years that had passed brought the company family even closer together.

The first years after the war are marked by hunger, scarcity and uncertainty: raw materials are in short supply, infrastructure and transport links are destroyed, and the economy is in ruins. And yet, amid the rubble, hope for a new beginning begins to sprout.

It is the "zero hour" of post-war Germany. Emil Frei also lays the foundations for the future during these years. With entrepreneurial sensitivity and his very own management style, he leaves his mark and memories on the company.

Döggingen, early 1950s. Karl Sättele really only wanted a temporary job cleaning buckets in the paint laboratory. "I thought an apprenticeship would be too difficult for me. When I wanted to quit, the senior manager said: 'We're so happy with you – you can do an apprenticeship here too!'" And so Karl Sättele became a paint laboratory technician and later head of quality assurance final testing in the liquid paint division.

Emil Frei also supported his employees in their private lives. For many, "the senior" was a kind of father figure. Sometimes he would put a few sweets in their pay packets, at Christmas he would hand out gifts, or he would help them furnish their new flats. It is these small gestures that have created the strong sense of family at FreiLacke.

Hans-Peter Frei still remembers his grandfather's gifts well, but also what he taught him about business. "For a long time, there was a sign in the conference room that read: 'Dear customer, dear supplier, if you are not served within the next five minutes, please call me personally. This encapsulates much of what is still part of FreiLacke's recipe for success today – even if one person alone can no longer take care of everything personally.

Emil Frei, on the other hand, loved his inspection rounds until the very end. "You could usually smell him first, because he always had a cigar in his mouth," says Erich Neubauer, who started as a trainee and later became sales manager for the industry. "Then he would suddenly be standing behind you – with his German shepherd – and ask, 'What are you doing?'"

FreiLacke now employs more than 600 people worldwide and is a technically and organisationally modern company. This is evident in large company celebrations as well as in key areas such as the promotion of young talent. And it continues to be evident in the little things: in an open ear despite a busy daily routine. In a helping hand for colleagues. In a trusting conversation with long-standing customers. Then the spirit of the company's founder, Emil Frei, is still alive.

The economic miracle years. It is a time of lavish Christmas parties, pork ribs, sauerkraut and gift baskets filled with pickled cucumbers. It is a time of change, growth and transition. At FreiLacke, these years are characterised by the then-dominant technology of liquid paints, the smell of solvents – and constant change.

No sooner has a renovation been completed on the FreiLacke company premises than it is already outdated. The laboratory staff have just been given their own seats by the window. A real luxury, but one that also has its disadvantages. This is because a public road runs beneath the window front, across the depot and on to the cemetery.

"Funerals were a strange situation," says Walter Bank, who began his training in 1962. At that time, horse-drawn carriages pulled the hearse. The laboratory staff were instructed to vacate the window seats until the funeral procession had passed through the courtyard.

It's not just because of its location that you're right in the middle of village life. The FreiLacke family has its own float at Fasnet, its own team that takes part in local tournaments. And the boss, Emil Frei, is everywhere as the head of the family. "Emil Frei would drop by from time to time, take a shot and then leave again," says Alfred Komander. "Since then, it's been called an Emil Frei bomb."

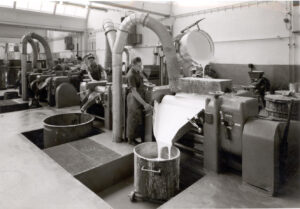

It is a time of two speeds. On the one hand, a new era is dawning – growth, prosperity, increasing supraregional competition. On the other hand, Döggingen, where FreiLacke has its roots, is still strongly agricultural. Many employees arrive at the production facility at dawn so that they can still work on the farm later in the day. The working day is less tightly scheduled, testing procedures can take years – in open-air weathering, results can only be read after 24 months at the earliest – and much of the work is done with a sense of proportion and muscle power.

"When a lorry arrived, everyone was rounded up. We then formed a line to unload the sacks," recalls Walter Bank. To ensure that the men had enough strength, each member of the production team was given half a litre of fresh milk from the dairy – bottled in glass bottles labelled with their names. On Saturdays, Emil Frei would come by and treat his staff to a crate of beer.

These are the times that many refer to as the "good old days". Before digitalisation, before the race for technological advancement, before automation. In 1966, a new era began at FreiLacke. A generation with many ideas took the helm.

Three brothers who could hardly be more different.

Emil Frei Junior, the youngest, is a personality you won't forget. He gained entrepreneurial experience early on during his apprenticeship and while working in the field in Döggingen. He is generous, charismatic and always has an open ear for people.

Franz Frei, the eldest. His years as a prisoner of war left their mark on him. He is serious, somewhat strict – and always has a box of apples in the boot of his car as emergency provisions. But at company parties, his sociable and warm side comes to the fore. Franz Frei is a passionate tinkerer, a technician who thinks outside the box. In 1967, he founded Donauplast, a pioneering company in the field of fibreglass-plastic manufacturing, which produces products for the aerospace industry, among other things.

And then there's Erwin Frei, the middle one. He's feared for his eagle eyes, which he uses to monitor the company's expenses. He's precise – so precise that he always finds a mistake when he looks for one. Especially in expense reports. And he loves stamps.

In 1966, Emil Frei senior handed over management of the company to his three sons. Emil Frei junior became a personally liable partner, Franz Frei, a graduate engineer, took over technical management, and Erwin Frei took charge of financial supervision. It was this unique combination of different talents, perspectives and strengths that caused friction – and at the same time formed the basis for the family business's great success.

The three brothers achieve decisive breakthroughs in several areas – on demand, so to speak. FreiLacke develops a coating for Stihl using powder coating technology, which was still untested at the time. The test phase lasted five years and required significant investment. In the new department, the colleagues' evening experiments, in which they attempted to coat magnesium die-cast chainsaws without bubbles, sometimes ended in disaster.

But their courage and extra shifts paid off. In 1973, Erich Neubauer and Edmund Heintschel opened the oven, released a wave of heat – and could hardly believe their eyes. "We looked at each other and said: 'Bingo, we've got it!'" recalls Erich Neubauer.

It was the beginning of an unbroken success story for environmentally friendly powder coatings that continues to this day.

At the same time, FreiLacke is taking on another challenge: developing a white electrocoat paint (ETL) for lamp manufacturer Ludwig Leuchten. The advantage of this technology is that two poles in the tank generate a voltage field that attracts the particles and ensures that they reach even the most remote areas of a component. This fully automated process ensures that even the intricate interior of lamps is coated evenly.

Young paint engineer Wolfgang Lindemuth took on the challenging task of developing a pure white ETL. To do so, he needed the ten-chain alcohol decanol. "Every time I opened the oven, a cloud of vapour came out. After three months, they kicked me out of the laboratory to get rid of the smell," he says. But Lindemuth kept fighting – and after nine months, he got the ETL plant up and running. Shortly afterwards, FreiLacke was supplying almost the entire German lighting industry.

It is a new stage in FreiLacke's exciting journey, which begins with the second generation. And soon, the family business will be moving out of its experimental field in the Black Forest and into the big, wide world.

The fully loaded lorries bearing the name "Emil Frei" are no longer confined to the Black Forest. They now travel across the country, for example to temporary storage facilities in the Rhineland and Hamburg, or over snow-covered mountain passes to customers in Italy. And more and more often, employees from Döggingen are crossing the borders of the Federal Republic of Germany heading east.

The German economic miracle finally reached its limits in 1973. Many companies relocated their production to the Eastern Bloc, and the Döggingen-based family business also established contacts there. Thanks to new sales markets, FreiLacke managed to remain successful on the market and continue to grow. In 1984, the company produced over 10,000 tonnes of paints and varnishes for the first time in a single year – 15 per cent of which was already destined for foreign markets.

The coatings developed specifically for containers are a major international success. Renate Strohmayer heads the department in the late 1980s and travels all over the world. Her first assignment takes her to China. Even the journey there was an adventure: she got stranded in Hong Kong, but finally made it to Shanghai – where she demonstrated her assertiveness. "The deputy director kept switching to Chinese. Finally, I got up and walked out. That was a loss of face for them. I was brought back in, and we were able to continue the discussion in English."

While the employees travel around the world, the digital age arrives in Döggingen. In 1983, a modern computer system replaces the old Ormig system. At the time, many people fear being replaced by machines. Communication, on the other hand, is still rather outdated: if one of the managing directors receives a call via the switchboard and is not at their desk, the legendary farm horn is used. "It honked once for Emil Frei and twice in a row for Franz Frei," says Klaus Schlautek, who was a paint laboratory technician at the time. Depending on where the bosses were, the "beep" and "beep-beep" could go on for a long time. "It was terrible honking at times."

FreiLacke is growing, becoming more modern and more international. But despite its success, enormous growth rates and internal restructuring, the family atmosphere in Döggingen remains intact. Emil Frei also takes care of his employees' personal concerns and is there when someone needs help. And celebrating together is part of everyday working life. "When it was Franz Frei's birthday, the whole laboratory team got together," recalls laboratory secretary Edith Muffler. "Once I crocheted him a tie out of fibreglass. We always had a lot of fun with him."

But the legendary era of brothers Emil, Franz and Erwin Frei is drawing to a close. And for the time being, there is no clear successor in sight.

When brothers Emil, Franz and Erwin Frei decided to retire in 1990 due to their age – Franz Frei was 69 and Emil Frei was 64 – they could look back on 24 years of growth, some of it in double digits. They had turned a small family business in Döggingen into an internationally successful company with 300 employees and renowned industrial customers.

But to whom should they hand over their family business?

The next generation is not yet ready to take on this legacy. Franz Frei's son Hans-Peter Frei has only been with the company for a few months. Rainer Frei, Emil Frei's son, is still studying. Emil, Franz and Erwin therefore decide to hire external managing directors on a temporary basis. The brothers retain a say in the company through an advisory board.

The transition phase lasts ten years. Not all decisions made during this time are uncontroversial or run smoothly. However, the unbiased outside perspective, innovative ideas and new perspectives brought to Döggingen by the non-family managing directors challenge the established structures of the traditional company – and have a lasting impact on FreiLacke.

In 1992, Rudolf Luley took over as managing director. He introduced a quality audit, standardised work processes and set new long-term goals. The entrepreneur, who had previously worked for a competitor, also pushed through the sale of the traditional painting division to the Sto company. However, just one year after taking office, Rudolf Luley died as a result of a tragic bicycle accident.

He was succeeded in 1993 by Dr Kurt Fahrenbach. The former CEO of a film manufacturer is not an expert in coatings, but he brings a new, decentralised and modern management style to Döggingen. He introduces calculations for representatives and working groups, questions existing working methods and, at the same time, continues and expands traditions such as employee activities that promote cohesion and team spirit.

This is how the "generation gap" becomes a strategically important phase. "It has helped the company move forward," says Dr. Rainer Frei today. "During this time, a lot of responsibility was shifted to the department head level, which continues to shape us today. As a medium-sized, family-owned company, I think we are very advanced in terms of collegial management styles."

What does the future hold? No one can answer this question with clarity and conviction these days. Much is in flux.

The Berlin Wall has fallen, and the Maastricht Treaty establishing the European Union has been signed. The massive investment needs in the East are fuelling an economic boom and a great deal of investment enthusiasm. But how high is the risk? How will the German economy develop overall? And how can one position oneself strategically in a European market with growing competition?

In "Vision 2010" – a collection of guiding principles and goals – FreiLacke attempts to find answers in a time full of unanswered questions. Among other things, the company aims to further establish itself as a system provider and build on its own values and strengths as an established family of companies.

Many internal processes are restructured during these years. FreiLacke invests specifically in the technology of the future and in its employees. In 2000, a new powder coating production building with a training centre is put into operation in Döggingen. The company has been participating in the eco-audit since 1996, thereby committing itself to continuously developing environmental standards and transparently disclosing progress and challenges. In 2003, Dr. Rainer Frei and Hans-Peter Frei take over the management of the company.

The third generation does many things differently than its predecessors. Among other things, it brings a new "green awareness" to the company. At the same time, it holds fast to proven traditions and adapts them to current requirements.

Because sometimes the answers to the questions of the future can also be found in the past.

This was the basic idea of company founder Emil Frei, who began manufacturing his own products in 1926 in order to respond individually to customer requirements. This customer focus has proven itself throughout all the upheavals – even if today it is no longer about paste and paints for craftsmen, but about system solutions for international industrial customers.

At the same time, Dr. Rainer Frei and Hans-Peter Frei remain clearly committed to their home town of Döggingen – yet still allow the family business to grow internationally. In 2006, FreiLacke establishes a subsidiary in England. Others are soon to follow.

Not everything was better in the "good old days". For a long time, it was part of everyday life for employees to be sprayed with paint from head to toe in the evenings. "The paint ingredients were mixed together manually," recalls Helmut Trenkle. "First, the liquids were added, such as resins and certain thinners. The other ingredients were then added while the mixer was running. Because there was no ventilation, it naturally created a lot of dust."

However, FreiLacke developed a new awareness of sustainability and safety at an early stage. The company invested in ventilation systems as well as noise and fire protection. Critical substances such as solvents were continuously reduced, and FreiLacke focused on environmentally friendly technologies such as powder coatings and low-VOC to VOC-free coating systems, such as the EcoOne electrocoat.

On the one hand, the family-owned company cares deeply about the safety and health of its employees and the natural environment of its home region. On the other hand, FreiLacke has positioned itself early on in the market as an innovative manufacturer and attractive employer with its sustainability projects, healthy working environment and ambitious environmental goals.

Back in 1995, the Döggingen-based company was one of the first paint manufacturers in Germany to be certified according to DIN ISO 9001. In 1996, FreiLacke passed the EU eco-audit (now EMAS) and voluntarily committed itself to transparently documenting its operational processes and products as ecologically sound. The focus here was on resource efficiency.

"This starts with the selection of raw materials and influences all processes, the working environment of employees and customer applications," says Rainer Frei. In 1995, for example, 15,700 m³ of fresh water was still required in Döggingen. Thanks to the use of rainwater for machine cooling and sanitary facilities, this figure had fallen to just 3,300 m³ in 2011, despite a sharp increase in production volume. In another project, FreiLacke reviewed its cleaning processes and developed a new cleaning system that reduced VOC emissions by 98 per cent.

Thanks to this and many other projects, FreiLacke has received numerous awards in recent years, including the Responsible Care Award from the chemical industry in Baden-Württemberg, an EMAS Award and a place on the prestigious list of "100 Companies for Resource Efficiency" compiled by the Ministry for the Environment, Climate and Energy in Stuttgart.

"Environmental protection and economic efficiency are not mutually exclusive," emphasises Hans-Peter Frei. "We will continue to intensify our efforts and investments in these areas." One goal is completely climate-neutral production. Since the 1990s, CO₂ emissions in production have already been reduced by 88 per cent.

When it comes to sustainability, the new times are good. And they will be even better in the future.

September 2019. Around 1,800 people gather on the company premises to celebrate the opening of the new powder coating production facility. Among the guests are employees from Döggingen, but also from subsidiaries and sales partners from abroad. As usual, everyone pitches in – colleagues, clubs, pensioners and business partners.

The day before, the entire workforce had gathered in the Donauhalle, where the current status of the Long-Term Positioning 2026 (LPF 2026) was presented.

This sunny weekend shows where FreiLacke's heart lies – and what plans the company has for the future: digitalisation, tapping into international markets, innovative customer projects, construction projects. But as the saying goes: life happens while you're making plans.

December 2019. International press agencies report on a "mysterious lung disease". The first lockdown follows, and orders plummet dramatically. But there is no sign of shock paralysis in Döggingen. A crisis team is formed, a hygiene concept is developed, and employees switch to working from home. Thanks to short communication channels, a relationship of trust with customers and partners that has grown over decades, and the great commitment of the workforce, FreiLacke manages to manoeuvre flexibly through the constantly changing exceptional situation of the Corona crisis – which is followed by the next turning point in February 2022 with the war in Ukraine.

2016 to 2026 is a decade of global crises. And yet FreiLacke has implemented many of its plans. The inauguration of the new powder coating production facility will be followed by the opening of the new administration building in July 2020. After establishing a key location in China in 2015, further subsidiaries are added in Sweden, the USA (2017), Mexico and Turkey. Also in 2020, after eight years of implementation, a new central ERP system goes live.

But despite growth, digitalisation and internationalisation, FreiLacke remains one thing above all else: a big family.

The fact that people are the focus here is evident in many areas. For example, in the new canteen, which opened in 2016 and was designed based on employee requests, but also in lively Christmas parties and joint hiking days. This sense of togetherness is evident in the fact that people can talk about problems – and also in awards such as "Best Employer in Baden-Württemberg", which are based on anonymous employee surveys conducted by the research company Great Place to Work®.

The long-term strategy projects also reveal where FreiLacke's heart lies: on the one hand, in Döggingen, the location to which the family business has been committed for 100 years. On the other hand, with its customers and the challenges that can only be solved with experience, expertise and trust.

The implementation of the Long-Term Positioning 2032 (LPF 2032) will begin in 2026 – even though no one knows what the future will bring. However, based on the past 100 years, FreiLacke knows that goals can be achieved when everyone works together.